|

Violin wood density |

|

Density values (The lowest figures correspond to 6% moisture content and the highest to 12%). Take care not to confuse a high density at 12% moisture content in the wood with a very low density at 0% moisture content.

Maple Spruce Low density 0.54 to 0,62 g/cm3 Low density 0.34 to 0.39 g/cm3 Average density 0.63 to 0.71 g/cm3 Average density 0.40 to 0.46 g/cm3 High density 0.72 to 0.78 g/cm3 High density 0.47 to 0.50 g/cm3

The overall properties of wood depend on its quantity of free water and mass of polymers. Briefly, the wood’s stiffness increases with its density and decreases when its moisture content rises. Water acts as a plasticizer, modifying the mechanical properties of the wood: the higher the moisture content, the lower the celerity and elasticity. Water diminishes the stiffness of the material by softening the mass of polymers.

The density curve is proportional to the moisture content. As the curves charting celerity and elasticity are inversely proportional to that of the density, the frequency of a material is inversely proportional to the curve of its moisture content.

High density always compensates for low elasticity as well as low compressive strength in free materials of equivalent weight.

The disadvantage of very low-density wood is that it nearly always has very low elasticity: the back tends to become deformed under pressure from the strings, raising the B1+ mode frequency by 20 Hz. Therefore, when tuning the free back plate, this expected rise in frequency must be taken into consideration.

On new instruments, average or high densities are preferable, because in certain cases, they compensate for low elasticity. In a back or top plate with equal weight, resistance to bending is always greater on the low-density material. On the average, wood loses 6% of its weight over the years, but increases in elasticity, whatever the density.

Some old instruments have been found to have very low-density top and back plates: this is not accordant with the reality of the original materials. After three centuries of natural ageing, top and back plates lose, on average, 6% of their weight. The density of the materials has decreased by approximately6% to 8%. These figures are comparable to those obtained by heating the wood at 195° in order to degrade the hemicelluloses.

N.B. It is essential to distinguish between a low-density material at 0% moisture content and high density at 12% moisture content on a material that is full of water which justifies the use of a moisture tester for wood.

WOOD CHARACTERISTICS AND PROPERTIES

In nature, it is impossible to find woods having identical characteristics, even within a single tree.

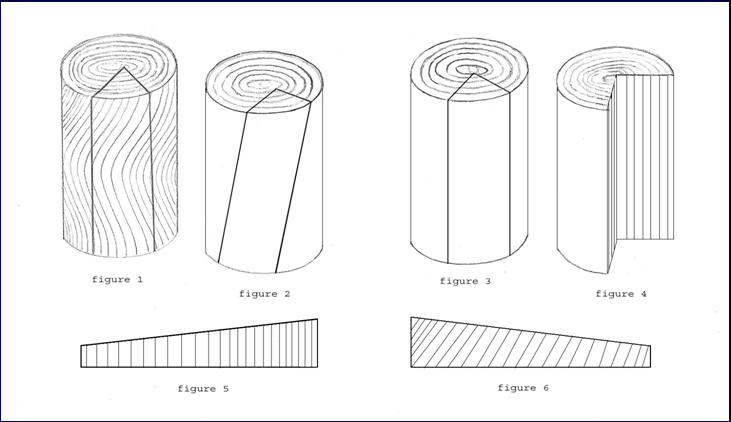

- Figure 1. The trunk turns left, then right (levogyre and dextrogyre). When this serious defect occurs, it is generally found at the base of the tree trunk.

- Figure 2. A slanting axial cut constitutes a major defect, more serious that slanted rings visible

In these two types of wood, the grain reverses constantly on both surfaces of the wedge, considerably decreasing the mechanical properties and increasing the difficulty of working the material. Such woods also have an extraordinary capacity for water absorption. A top plate having a slanting axial cut behaves as if the entire surface of both the extrados and the intrados were of end wood. The frequency of these materials is utterly unstable, even after lengthy dehydration, and remains unstable years later. They must be eliminated from violin making.

- Figure 3. Tone wood must not only be quarter-cut, but also on the vertical axis of the tree trunk.

- Figure 4. Two growths are visible on spruce and maple: spring growth (white) and summer growth (brown) or late growth ring. Growing conditions can modify the difference in density between the two growths. Widely spaced rings increase the density of the summer growth and decrease the density of the spring growth. Very narrow rings decrease the density of summer growth and increase the density of the spring growth. Wood’s elasticity is mainly due to the late rings. Very narrow rings decrease the width of the summer growth, which lowers the wood’s overall density and elasticity. To obtain high-performance materials, spruce should thus be selected according to the following criteria: regular but not too narrow rings and strongly marked late rings.

- Figure 5. The best materials are cut on a straight, vertical axis, but also have regular, perpendicular growth rings that are parallel to each other. They have great mechanical strength and outstanding acoustic performance. They are also easy to work.

- Figure 6. Slightly slanted growth rings have little effect on the mechanical and acoustical properties of the materials. Their hydrophilic capacity is normal.

Whatever the direction used in planing or scraping, any wood that fuzzes up on the surface must be eliminated from violin construction, due to high hydrophilic capacity and very low strength.

The modern violin maker’s choice of wood is often based on his/her sense of esthetics. Close examination of certain old instruments reveals blatant defects in the growth rings or flaws in the instrument’s appearance. Italian violin makers valued the materials’ performance over their beauty.

It is commonly believed that the lightest-weight wood makes the best violins. Low weight in a top or back plate does not necessarily prove it was made from low-density material. The extremely fine thicknesses on Guarneri or Stradivari violins testify to their use of materials having high elasticity (both longitudinal and transverse) and average or high density at the outset.

The acoustic properties of tone wood change over the years. The moisture content of the wood absorbs vibratory energy, converting it into calorific energy (heat) by evaporation. Although the wood used in violins is already dry, changes in the free water content of the wood will affect the instrument’s acoustics through modification of the elasticity modulus, viscoelastic performance, and frequency. Long-term improvement in the acoustic response depends mainly on the breakdown of hemicelluloses, the wood component that most readily absorbs free water. With the passing years, hemicelluloses degrades and the wood’s free water content decreases, as do the density and weight of the materials. The wood’s moisture content is then at its lowest level, and consequently, the frequency of the plates, free or assembled on the ribs, rises.

The choice of wood is the primary determinant for an instrument’s acoustical qualities. In order to create a solo violin, the back and top plates must be tuned in a restricted frequency spectrum using materials with minimal weight yet maximal strength.

To select their wood, violin makers customarily tap the unworked plates in order to learn how and how long they ring, but this does not suffice.

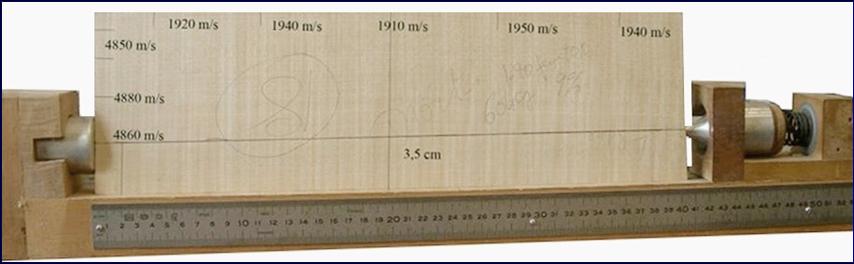

Although knowledge of the wood’s celerity and elasticity is not necessary to choose the raw materials for the plates, it is essential to know the height of the frequency of the materials before commencing manufacture of an instrument.

Treatment of wood

As for the wood of old instruments: they have lost a large part of their hemicellulose through natural processes. Consequently, their maximum capacity for absorption of free water has been nearly halved, and the spread of the B1– and B1+ mode frequencies is likewise halved. The moisture content in the wood rarely exceeds 8%.The Italian violin makers may have used one or more techniques to accelerate the destruction of hemicellusose that is so greedy for free water.

Heat treatments prevent the materials from reabsorbing humidity beyond 8% moisture content. Prolonged exposure of the plates to the sun or to UVs limits the wood’s capacity to reabsorb moisture beyond 8% after the instrument is varnished. Thus, the amplitude (spread) of the top and back plate coupling frequencies and B1-, and B1+ mode frequencies is reduced.

N.B. To obtain a soloist violin, the B1- and B1+ mode frequencies must be tuned in a restricted frequency spectrum and must remain relatively stable under various conditions of temperature and ambient humidity.

The Italian instrument makers were perfectly aware of the problem posed by the variability of plate frequencies depending on the temperature, ambient humidity, and the season. String players also face this disadvantage when the moisture content of the wood alters the sonority of their instrument. Cellos are the most sensitive to such changes.

Each time a reading is taken of the B1- and B1+ mode frequencies of a violin (new or old), a change in these mode frequencies will be observed, according to the ambient humidity, temperature, and season.

Heat treatment

Wood contains two forms of water: free water and the water that is bound to the molecules. Under certain conditions of ambient humidity, wood can be naturally anhydrous (no free water in the wood).

Heating the wood is a technique that enables the use of recent wood under better conditions.

Heating the wood to 150/160 °C sets off deterioration of hemicellulose that is so greedy for free water. Dehydration and creep operated on the free back and top plates accelerate this process, thus limiting to 8% the moisture that can be reabsorbed by the materials.

Heating wood does not improve its intrinsic properties, but makes the materials perform better under conditions of high ambient humidity (70% to 80%). This is the desired outcome.

Since water acts as a plasticizer, moisture content between 10% and 13.5% modifies the materials’ damping significantly. The performances of the wood are considerably diminished. The purpose of limiting the hydrophilic capacity of the materials is to limit the frequency amplitude (spread) of all body modes of the violin (in the white or varnished).

Without heating the unworked wood and inducing creep in free materials, the amplitude of the mode 5, B1– and B1+ frequency in the white between the rates of 12% and 1% is between 36 Hz and 42 Hz.

This frequency amplitude must imperatively be reduced to approximately 12/14 Hz between moisture content levels of 8% and 4% (the normal conditions of violin use) by subjecting the materials to heating and creep.

Therefore, it is necessary to heat unworked wood and to subject free materials to creep in order to reduce their capacity for moisture absorption to 8%.

Heating tonewood with moisture content below 6% is not advisable.

The heating of the wood must be homogeneous and must follow a strict procedure, otherwise the materials may split or become deformed for the following reasons:

- Exothermia: The difference in temperature between the surface and the heart of the wood is too great. The rise in the material’s temperature is too rapid.

- Endothermia: The difference in temperature between the heart and the surface of the wood is too great. The material’s temperature has decreased too rapidly. The materials must be left in the oven to cool down to the ambient temperature.

Creep (in French: fluage)

Creep is a physical phenomenon that (in violinmaking) consists in subjecting materials to a constant constraint under relative humidity cycles (with a maximum and minimum level) to provoke irreversible deformation. In the event of moisture content of 12% followed by considerable retraction after dehydration of the wood (to between 2.5% and 0%), the wood's capacity to resorb moisture is reduced over the course of years, and the variations in the mode frequencies of the violin back and top plates are lessened.

The best solutions for modifying the material’s behavior consist in prolonged exposure of the free back and top plates to sunlight, or to UVs in a closed cabinet at 40 °C (104 °F), or natural dehydration of the wood below 6 % moisture content.

When creep is induced before assembling the body, the variation (amplitude) in the frequency of the free back and top plates in the white between moisture content in the wood of 12% to 0% is approximately 24 Hz. Without prior creep, this variation may be as great as 36 Hz.

Over the course of years, the wood will be subject to considerable creep: all of the mode frequencies will rise naturally and may exceed the critical limits, if the violin maker has failed to take the necessary precautions before varnishing the instrument.

Experimentation on wood samples does not always yield the same results as on a violin. The extreme thinness of violin plates makes this instrument very sensitive to creep in the wood, accelerating the degradation of hemicellulose that soaks up free water.

Prolonged exposure of a free violin plate to the sun is similar to low-temperature kiln drying. As materials dehydrate, they shrink and stabilize at a minimum value. Dehydration reduces the wood’s capacity for resumption of moisture content back to 12% after the instrument has been varnished. After the moisture content increases, there is very little, if any, elongation of the wood. Overall stability is therefore increased. This particularity is visible on old instruments whose back plates shrank considerably after prolonged exposure to sunlight, giving their surface a corrugated aspect.

The main problem encountered in violin making is an uncontrolled dehydration of materials after varnishing, thus raising all the sounding box frequencies above their critical limits and making modes B1- and B1+ fall out of tune with each other. Many violin makers have observed that, in this case, the violin’s sound is aggressive, the strings saturate, and the warmth discernable before varnishing disappears.

Both old and recent wood reabsorb and lose moisture at the same speed. The wood of classic instruments (250 to 300 years old) has lost a large part of its hydrophilic hemicellulose, thus limiting the moisture content in the wood to between 0% and 8%. This is the reason for their acoustic qualities and stability.

Copyright © 2010 - 2019 Patrick Kreit. Reproduction of any content of this site without my express written permission is prohibited.

|